Cocarber®

Coffee Carbon Series

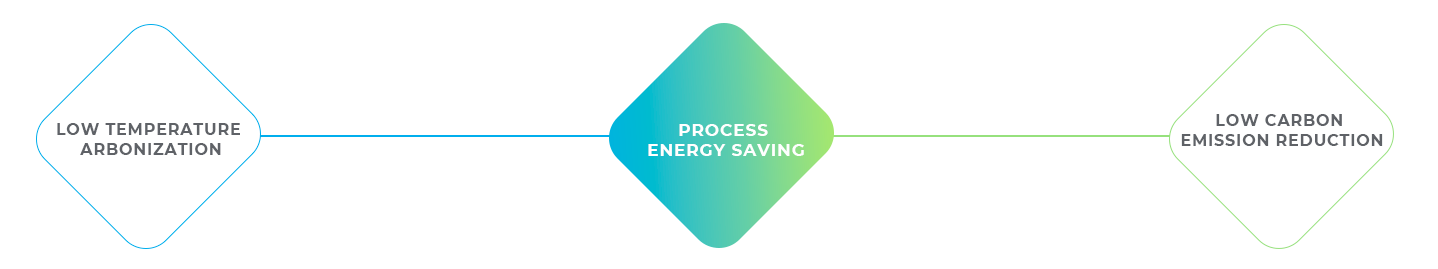

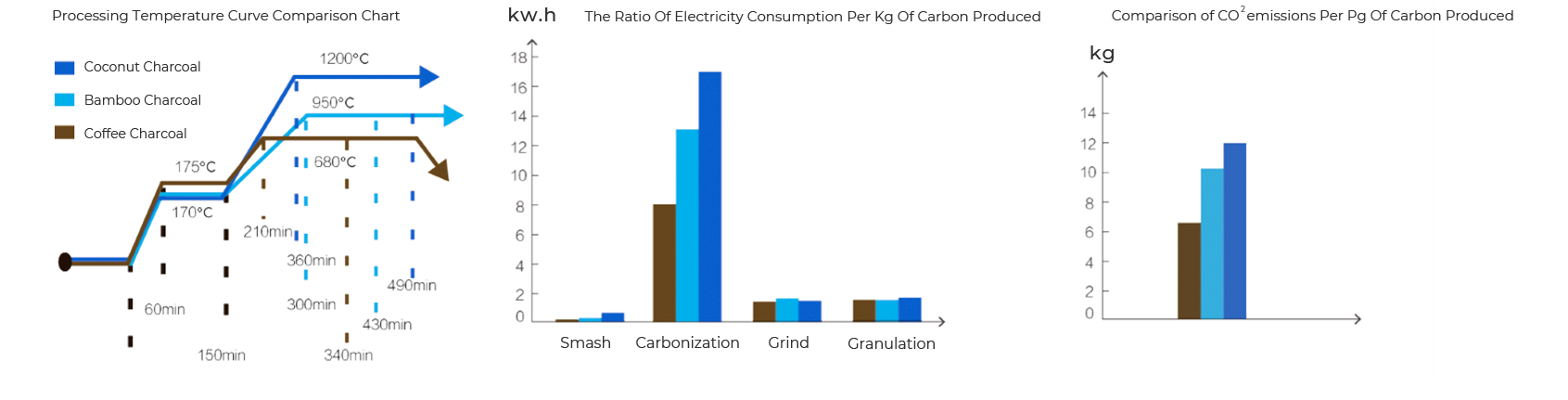

Low temperature carbonization: porous structure

Tannic acid: antibacterial

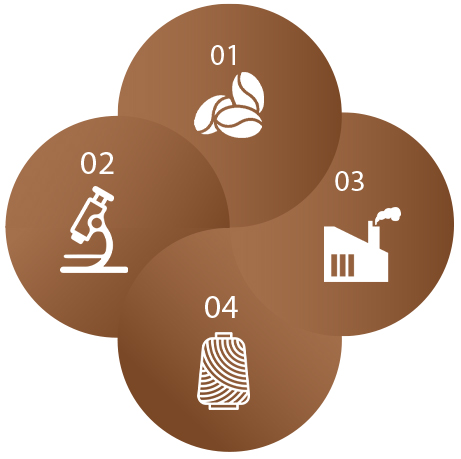

PRODUCT TECHNICS

Material selection

Recycled coffee grounds and made into coffee carbon by low temperature carbonization

Grinding granulation

Special grinding process to make carbonized coffee grounds into nano-sized powder masterbatch

Spinning

Advanced blend spinning process to ensure yarn quality stability

Post processing

Special texturing process to impart a change in yarn style (elasticity, floral ash)

PRODUCT FEATURES

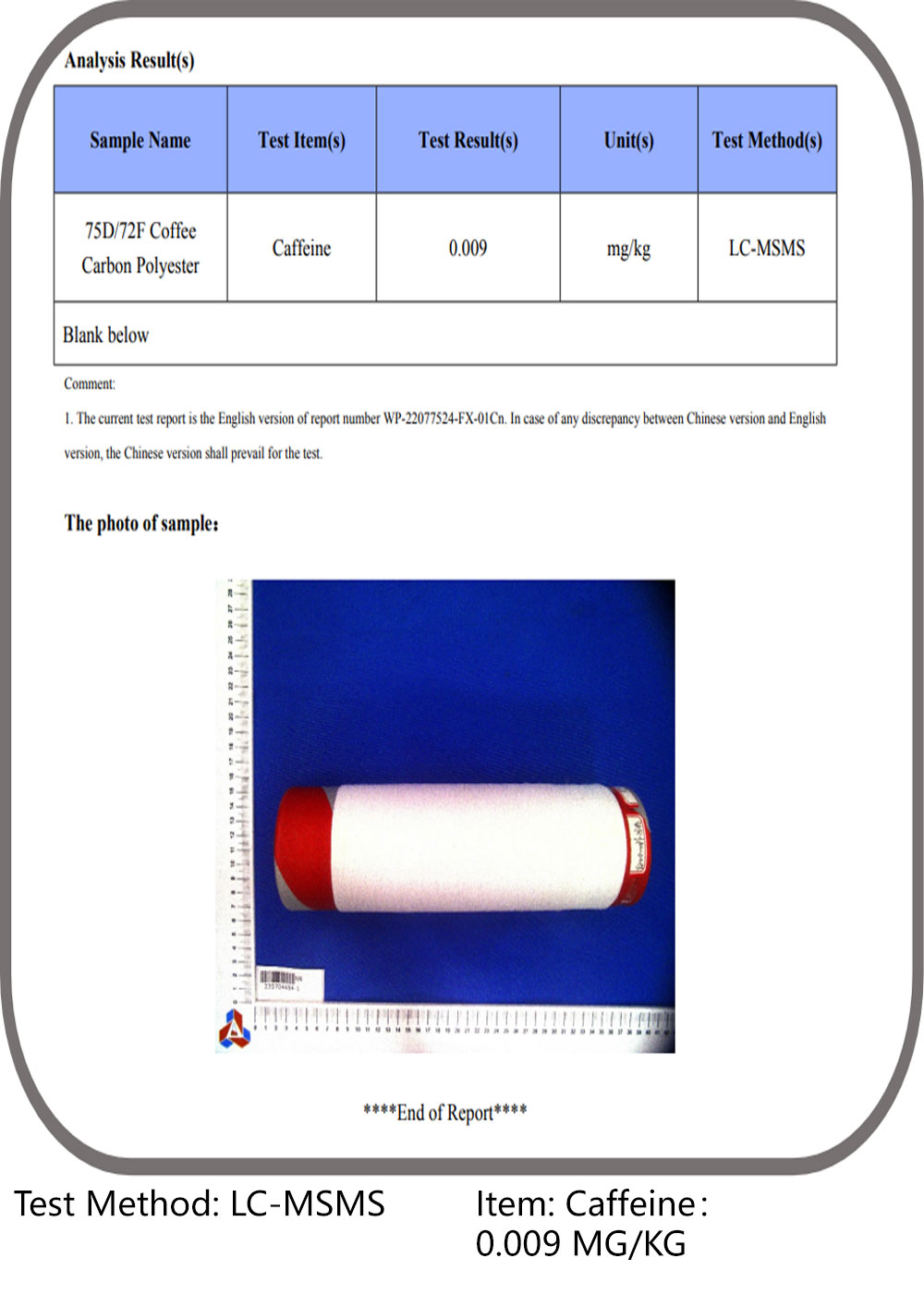

Antibacterial

The addition of carbonized coffee carbon in the fiber contributes the surface of the fiber to be porous, the surface area to increase, the surface activity, the adsorption and diffusion of the surface state are obviously improved, so that the product has the functions of sweat absorption and sterilization.

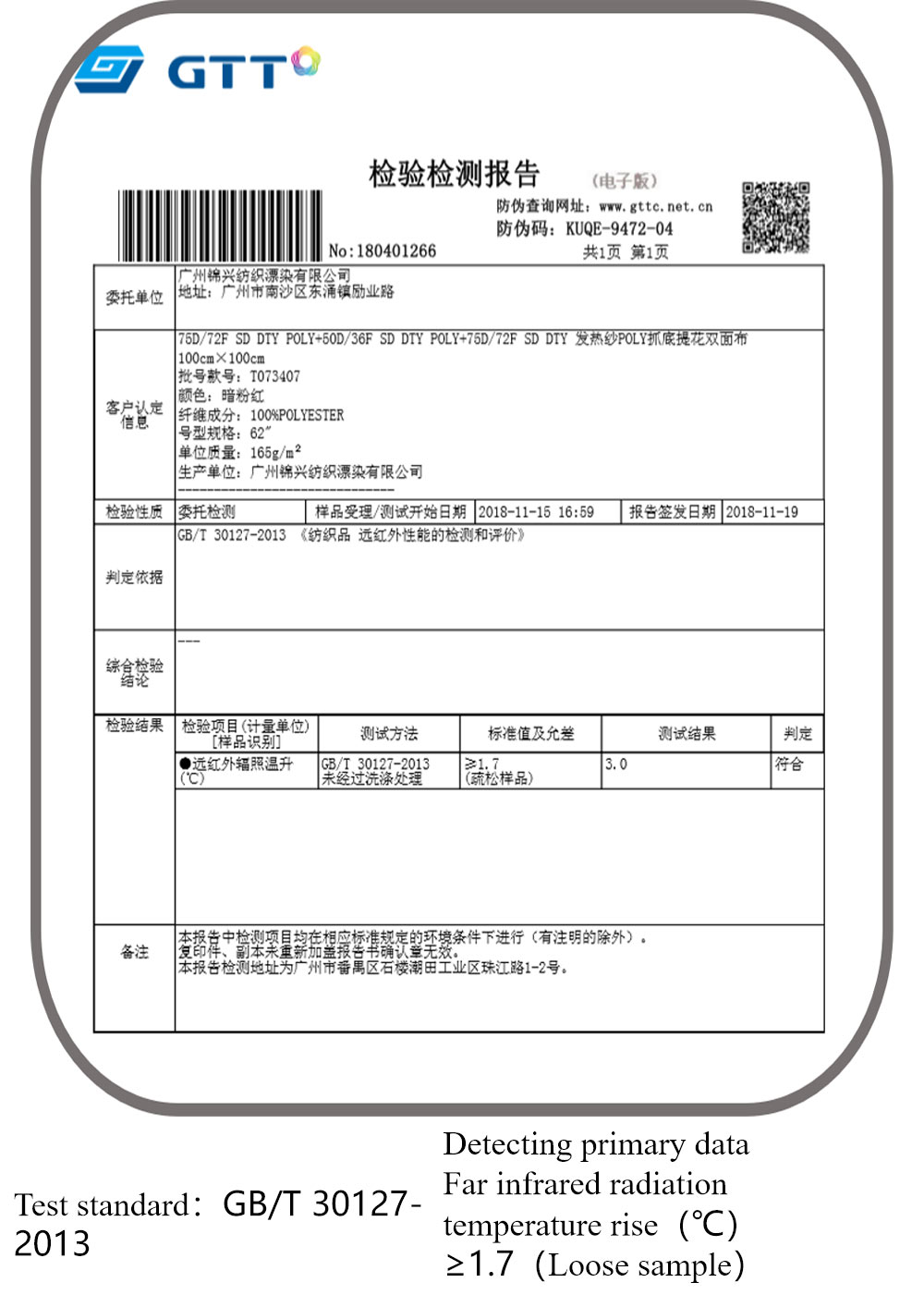

Thermal Retention

Make use of heat radiation from living organisms to absorb and store the ability of the outside world to radiate to the organism, so that the organism produces a “greenhouse effect” to prevents heat loss and plays a good thermal insulation effect.

health care

The heat absorbed by the skin can be circulated through the medium and blood, so that thermal energy can reach the body tissues and promote blood circulation and metabolism.

PRODUCT SPECIFICATIONS

Environment Friendly